Table of Content

Since many industrial processes have timescales easily addressed by millisecond response times, modern electronics greatly facilitate building reliable controllers, and performance could be traded off for reliability. Information technology, together with industrial machinery and processes, can assist in the design, implementation, and monitoring of control systems. One example of an industrial control system is a programmable logic controller . PLCs are specialized hardened computers which are frequently used to synchronize the flow of inputs from sensors and events with the flow of outputs to actuators and events. The automation of vehicles could prove to have a substantial impact on the environment, although the nature of this impact could be beneficial or harmful depending on several factors. Because automated vehicles are much less likely to get into accidents compared to human-driven vehicles, some precautions built into current models (such as anti-lock brakes or laminated glass) would not be required for self-driving versions.

An example of a pulse train you might generate to control a servo, as shown in a screen capture from an inexpensive digital oscilloscope, an instrument for observing voltages). Here, a pulse is generated once every 20 milliseconds, or at about 50 Hz. In this example, the pulse width is about 2 milliseconds, which would have a servo rotate almost all the way to one end of its rotation. An oscilloscope is incredibly useful for testing and debugging systems that use servos. Listed below are names and contacts for people who are interested in selling their quilting machines.

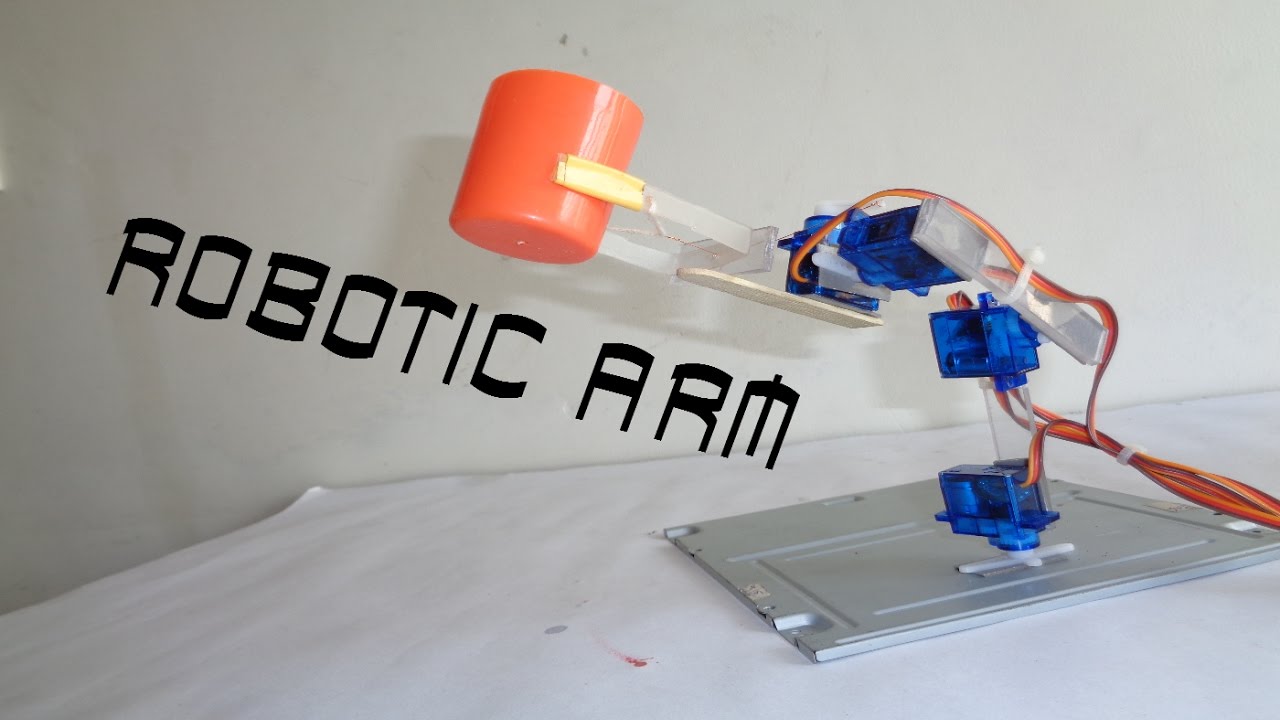

Controlling a servo motor

Simply navigate to the Run Job tab, and load the job you would like to run. On this tab, you are able to see the current part being machined, the next part to be machined, the number of completed parts, and the total number of parts to be completed. On the APL Scheduler tab, you are able to schedule multiple jobs in sequence. Once the job is loaded, you are able to able to assign the jobs an order number, which corresponds to the order in which the job will be run. Learn how to load parts into your machine using the Load Parts tab.

Expect more organizations to optimize data usage to drive decision intelligence and operations in 2023, as the new year will be ... Developed by Alan Turing, the Turing Test is a method of inquiry to determine whether an AI device (computer, robot, etc.) can think like a human being. Despite their increasing ubiquity, there are several shortcomings to using robots. Automate manual or repetitive activities in corporate or industrial settings. M. Greene, "Four bar linkage knee analysis," Prosthetics and Orthotics International, vol.

Sathi Limb

This synthetic nerve system enables prosthetic limbs sense braille, feel the sense of touch and respond to the environment. This is the process where heavy loads, be it raw materials or finished products, are picked by hydraulic robotic arms and placed in storage units or loaded into sorting machines. These loads are usually too heavy for human hands but easy work for a strong hydraulic robotic arm. A myoelectric prosthesis uses the electrical tension generated every time a muscle contracts, as information. This tension can be captured from voluntarily contracted muscles by electrodes applied on the skin to control the movements of the prosthesis, such as elbow flexion/extension, wrist supination/pronation or opening/closing of the fingers.

A recent study by the Delft University of Technology, The Netherlands, showed that the development of mechanical prosthetic hands has been neglected during the past decades. The study showed that the pinch force level of most current mechanical hands is too low for practical use. In 2017 however, a research has been started with bionic hands by Laura Hruby of the Medical University of Vienna. A few open-hardware 3-D printable bionic hands have also become available.

Haas Robot Package 1 Drawer Cart Demo

A limited number of organizations, such as the International Committee of the Red Cross , create devices for developing countries. Their device which is manufactured by CR Equipments is a single-axis, manually operated locking polymer prosthetic knee joint. The Icelandic company Össur has also created a robotic transtibial leg with motorized ankle that moves through algorithms and sensors that automatically adjust the angle of the foot during different points in its wearer's stride. Also there are brain-controlled bionic legs that allow an individual to move his limbs with a wireless transmitter.

The hovercraft uses two brushless motors, one for creating an air cushion for the lift, and the other for generating thrust or moving forward. Just like DIY RC Transmitter, this DIY Arduino RC Receiver can be used for many application. We can easily pair the two projects together and control anything wirelessly. Among others, I made an example of controlling a commercial RC car model using these DIY transmitter and receiver. The brain of this Arduino project is an Arduino Pro Mini board which is the smallest Arduino board. The radio communication is based on the NRF24L01 module, it has 2 joysticks, 2 potentiometers and 4 momentary push buttons.

We could not be prouder of, or more grateful to, the team we have assembled here over the last three years to build the publication. They are an inspirational group of people who have gone above and beyond, week after week. The important thing for our customers is the value we provide them compared to what they're used to.

This technology allows amputee patients to handle prosthetic hand systems in a more natural way. New plastics and other materials, such as carbon fiber, have allowed artificial limbs to be stronger and lighter, limiting the amount of extra energy necessary to operate the limb. Additional materials have allowed artificial limbs to look much more realistic, which is important to trans-radial and transhumeral amputees because they are more likely to have the artificial limb exposed. Prostheses are intended to restore the normal functions of the missing body part. Amputee rehabilitation is primarily coordinated by a physiatrist as part of an inter-disciplinary team consisting of physiatrists, prosthetists, nurses, physical therapists, and occupational therapists.

The earliest feedback control mechanism was the water clock invented by Greek engineer Ctesibius (285–222 BC). A hydraulic robotic arm is designed for a number of tasks, as we have already mentioned. Most of them are even flexible enough to be able to do more than one thing on the manufacturing floor. This hydraulically operated robotic arm uses extremely simple ideas as well as really simple mechanisms to achieve a complex set of actions and is also intended to imitate the action of operators.

In 1940, Sir Charlie Chaplin probably had no idea that the inexorable rise of machines was just a few decades away. Over 80 years later, automated robots are now used in manufacturing, industrial supply chains, agriculture, financial services, education and more. Not only does the patient need to pay for their multiple prosthetic limbs, but they also need to pay for physical and occupational therapy that come along with adapting to living with an artificial limb. Unlike the reoccurring cost of the prosthetic limbs, the patient will typically only pay the $2000 to $5000 for therapy during the first year or two of living as an amputee. Once the patient is strong and comfortable with their new limb, they will not be required to go to therapy anymore.

Current body-powered arms contain sockets that are built from hard epoxy or carbon fiber. These sockets or "interfaces" can be made more comfortable by lining them with a softer, compressible foam material that provides padding for the bone prominences. A self-suspending or supra-condylar socket design is useful for those with short to mid-range below elbow absence. Longer limbs may require the use of a locking roll-on type inner liner or more complex harnessing to help augment suspension.

While this autonomous system didn't make it past the drawing board, in 2004 a team of Italian scientists replicated its design as a digital model, proving that it works. RPA is a steppingstone to more advanced intelligent process automation . IPA adds decision-making capabilities, AI tools and cognitive technologies like natural language processing and machine learning.

It all begins when a signal is sent to the servo from the motion controller. Have you ever picked up one end of a rope that was tied to a tree or held one end of a jump rope while a friend held the other? Imagine that, while holding your end of the rope, you moved your arm up and down. The rope would make a big hump that would travel from your end to the other. What you have done is applied a pulse, and it traveled down the rope as a wave.

Hydraulic cylinders, as well as the hydraulic systems, will remain something of interest and if such a system is available, it is very easy as well as logical to use this system for the rotating drives of the cooling systems, as well. An important advantage of a hydraulic drive is its high power density as the mass of a hydraulic drive is several times smaller than the mass of an electric drive of the same power which makes its power density very high. Hi, Shrikant here ,i was working on a project ,i got a problem in my project, the problem is,i am trying to operate big motors using relays ,contactor relay,operated by arduino. The relays does not operate properly ,the loop does not get completed .The relays are not taking load contactor ,i think so. The main concern if you would like to build a real life example with lifting a car would probably be the lifting mechanism.

No comments:

Post a Comment